- Resources

- …

- Resources

- Resources

- …

- Resources

Low Volume Manufacturing

Low volume manufacturing is the best pathway to move from prototype to production smoothly and provides on-demand low volume production with the ability to quickly deliver custom parts.

What is Low-Volume Manufacturing

Low-volume manufacturing is a rapid production method that precedes full-scale production, ranging from 100 to 100,000 units. It does not require investment in expensive production tools, but reduces risk, allows design flexibility, shortens time-to-market, and creates opportunities for production cost savings. Additionally, it provides agility and quick turnaround for on-demand manufacturing in the supply chain.

Effective and Efficient Low Volume Production & Manufacturing

As product lifecycle shrinks and new product development cycles shorten, flexible innovation and time-to-market remain critical. To meet customization and diversity demands, production lines gravitate towards low-volume manufacturing

Advantages Of Low Volume Manufacturing

- More flexible design iterations

Creating low-volume manufacturing allows for more efficient verification of design, engineering, and manufacturability. - Short turnaround times and low costs

Tooling is cost-effective for low-volume manufacturers to handle orders quickly and flexibly, with no minimum order quantities. - Closing the gap in production

Low volume trial runs bridge the gap between prototype and production, timely identifying and resolving any issues before moving to mass production. - Reduced time to market faster

Low volume manufacturing services optimize the link between production to supply chain and consumer, providing rapid time-to-market for new products.

- More flexible design iterations

Low Volume Manufacturing Services

Ruiyang Precision is committed to a wide range of low-volume manufacturing services, including CNC machining, rapid injection molding, vacuum casting, metal casting, sheet metal, stamping forging, aluminum extrusion, and more. We continuously strengthen production management, process improvement, supply chain collaboration, and cost control to continuously improve customer satisfaction with fast, efficient, and competitive prices.

Sheet Metal Fabrication

Our fabrication capabilities include stainless steel, steel, aluminum, brass, red brass, galvanized materials, and fabrication of frames, equipment panels, enclosures, chassis, brackets, and more. We cater to sheet metal fabrication, from low-volume prototypes to high-volume production.

Rapid Injection Molding

We combine traditional injection mold machining methods with rapid mold manufacturing, ranging from voluminous test parts to on-demand molded parts. We handle the transition from small to mass production runs.

Low Volume CNC Machining

As a specialized manufacturer of CNC machining, we are equipped with advanced 3-axis, 4-axis, and 5-axis CNC machining centers to provide complex geometries and customized low-volume CNC machining for vast manufacturing requirements.

Aluminum Extrusion

Aluminum extrusion is suitable for manufacturing aluminum parts or profiles with consistent cross-sectional shapes, usually using aluminum alloy 6061 and 6063 material extrusion. It also supplements CNC post-processing, including drilling, tapping, etc.

Urethane Vacuum Casting

Silicone molds are made using additive manufacturing technology or CNC-machined masters to produce high-quality plastic-like polyurethane parts in low volume for functional testing and pre-production evaluation.

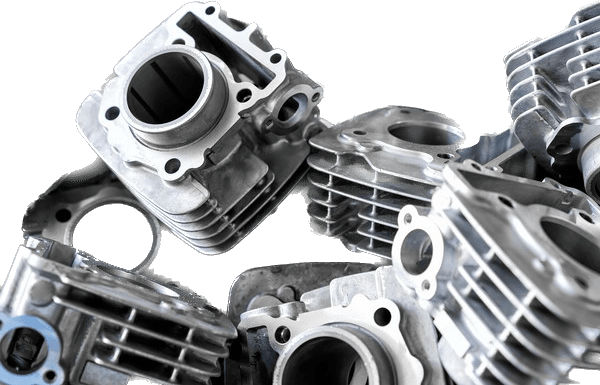

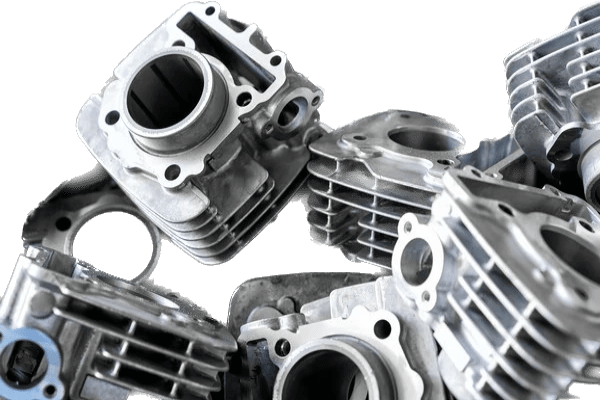

Rapid Metal Casting

We can provide pressure die-casting for aluminum, magnesium, and zinc, alongside investment casting for steel and copper. Additionally, we offer post-CNC casting finishing and flexible production methods for low-volume metal casting project requirements.

Let’s Start A New Project

Contact Us

Monday - Friday 9:00 AM - 5:00 PM

+86 18148951366

contact@